Heat management is crucial for the optimal functioning of electronic devices. If the heat generated by electronic components is not efficiently dissipated, it can cause damage and even result in system failure.

One of the most effective ways to manage heat is through the use of heat sinks. Heat sinks come in various types, and extruded heat sinks are a popular choice due to their cost-effectiveness and ease of manufacturing.

This article will discuss how extruded heat sinks work and how they improve thermal management in electronic devices. We will also explore the benefits and limitations of extruded heat sinks, along with some common applications.

How Does Extruded Heat Sinks Work?

Extruded heat sinks are a common choice for thermal management in electronic devices due to their high efficiency and cost-effectiveness.

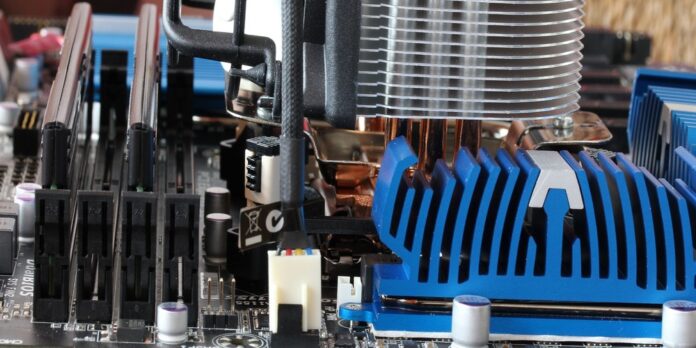

The design of an extruded heat sink involves pushing a block of metal, typically aluminum, through a die to create fins that increase the surface area for heat dissipation. This process creates a solid piece with no joints, making it more durable and reliable.

The fins of an extruded heat sink work by increasing the surface area in contact with the air, which helps in heat dissipation. The extrusion process allows for complex fin shapes, further improving the cooling efficiency.

What Are the Benefits of Extruded Heat Sinks?

The benefits of extruded heat sinks are numerous, making them a popular choice for thermal management in various applications. Some of the key advantages include the following:

High Efficiency

Maximizing thermal efficiency, extruded heat sinks offer superior performance by increasing the surface area for effective heat dissipation.

These heat sinks ensure optimum cooling even in demanding applications, making them a popular choice for a wide range of industries.

Cost-Effective

These heat sinks are relatively inexpensive to manufacture and can be customized to meet specific design requirements.

This cost-effectiveness of extruded heat sinks allows for efficient thermal management solutions without breaking the budget.

Versatility

Extruded heat sinks can be designed in various shapes and sizes, making them suitable for a wide range of applications.

Additionally, the versatility of extruded heat sinks allows for easy integration into complex mechanical and electrical systems.

Lightweight

These heat sinks are made up of lightweight aluminum, making them ideal for applications where weight is a concern.

Their lightweight nature also helps to reduce shipping costs and simplify installation, making them a cost-effective solution for thermal management in various industries.

Easy to Install

Extruded heat sinks are easy to install and require minimal maintenance, making them popular for many industrial applications.

These heat sinks are also durable and have a long lifespan, making them a cost-effective solution in the long run.

Applications of Extruded Heat Sinks

Extruded heat sinks have a wide range of applications thanks to their ability to manage heat effectively. They are commonly used in electronic devices, including computers, televisions, and mobile phones, to prevent overheating.

They are also used in automotive and industrial applications to dissipate heat generated by engines and other machinery. CNC machines also benefit from extruded heat sinks to manage the heat generated by the motor and control systems.

Kingka, a company specializing in thermal solutions for CNC machines, offers extruded heat sinks customized to meet specific requirements.

Conclusion

In conclusion, extruded heat sinks are an effective solution for thermal management in various industries. They offer cost-effectiveness, customization, and easy installation, making them an attractive choice for engineers and manufacturers.

With the constant need for efficient heat dissipation, extruded heat sinks will continue to play a vital role in electronics, aerospace, and CNC machines.